Core Technologies and Products

CISDI has achieved multiple major breakthroughs on steel engineering, research and development, and applications.

Environmental protection, intelligent, and high-efficiency stockyard

More than 40 domestic and overseas projects have applied CISDI's green, energy conservation and intelligent stockyard technologies, leading in performances of unmanned or less labored operation, consumption reduction, land and cost saving, and operation efficiency enhancement.

It is a critical promotional technology by the national environmental technology authority

CISDI's different models of new-generation green and intelligent stockyards

High-efficiency, low-consumption mega blast furnace

More than 20 domestic and overseas mega blast furnaces in a volume level of 4,000 cubic meters have applied CISDI's high-efficiency, low-consumption and intelligent blast furnace's design, equipment and control. They are or will be performing with world-class indicators.

It has been awarded an excellent Chinese patent.

Blast furnace's no-bell top

CISDI-developed no-bell top has been widely used for the large blast furnaces in Baosteel Zhanjiang, POSCO Indonesia and Formosa Ha Tinh Steel Vietnam plants. Their performances are leading the world.

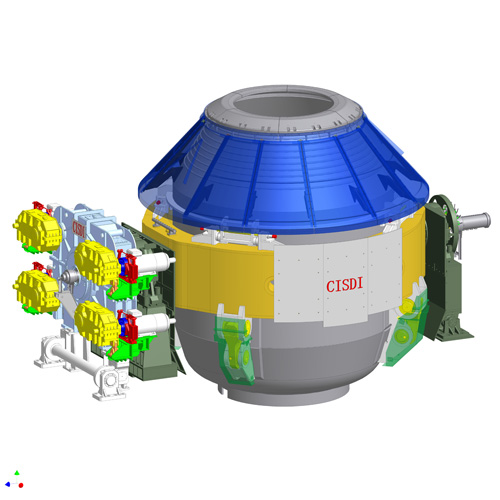

CISDI-SACS (self-adaptive constraint system) 4-point linkage suspension system

The world's initial four-point linkage suspension system for basic-oxygen furnace (BOF) is a patented technology of CISDI, seeing more than 10 BOFs' applications.

Green EAF

CISDI's green EAF is a great contributor to energy-conservative and environment-friendly steelmaking sector and reduces electric consumption by (60~100)kWh per tonne of liquid steel, compared with the conventional electric furnace.

Continuous caster

CISDI has made major breakthroughs in high-speed continuous casting of ultra-thick slab, bloom and shaped blank, flat blank, and billet.

Leading China's continuous casting sector, CISDI focuses on product mix upgrade, model optimisation, strand quality diagnosis and optimisation, casting equipment diagnosis and rebuild, casting process parameter calculation and simulation.

The billet casting speed in CISDI's design and references has stabilised at 3.75 meters per minute, and peaked at 4.08 meters per minute.

High-strength strip hot mill integration

CISDI creates the most competitive high-strength strip hot mill with the optimal indicators and the best cost- and energy-efficiency. Process design and equipment design and manufacture are fully homemade; electric, instrumentation and computer systems are well integrated.

ZLD

CISDI blazes a trail in realising ZLD (zero liquid discharge) in a metallurgical plant. Being an expert in advanced industrial waste water utilisation technologies, CISDI has achieved the target of less than 4 cubic meters of fresh water consumption per tonne of steel for solving the steelworks' water resources conservation and environmental protection.

A number of technological advancements have been made in urban construction, energy conservation, environmental protection, IT and smart applications.

Modernised steel structures

CISDI boasts about ten patented and proprietary technologies for modernised steel structures, including the ultra-large span (net shell, tensioned membrane, huge truss), high-rise steel structures package, huge storage, and prefabricated steel structures integration.

Geotechnical engineering

CISDI is an active player in complicated geotechnical engineering and research of eco-slope and novel hill support technologies.

Editor-in-chief of the municipal and industries' geotechnical engineering standards, CISDI is among the first batch of reserve for Chongqing rail transit safety evaluation and consulting organisations, and responsible for the technical reviews on all the constructions within the municipal rail transits' control areas.

Sludge/livestock's feces treatment

CISDI-OEAC is an innovative odorless, highly-efficient, aerobic fermentation package technology. Based on the modernised solid fermentation theory, it enables the traditional organic wastes composting to be a fully automatic and mechanised process, featuring high treatment efficiency, small footprint, no odor or zero pollution throughout the process. The fermented produce can be used as nutritive soils.

The self-reliant technology is shown a process flow below and applies to treat with sludge from a waste water treatment plant and the feces of domestic fowl and livestock.