Complete production process quality control underscores the success of CISDI’s NHCD short-stress path rolling mill

Date:2024/6/24 Source: CISDI

High rigidity, outstanding stability and regulating accuracy make CISDI Equipment Co’s NHCD short-stress path rolling mill a popular choice for steel organisations around the world.

The company supplies 800 to 1,000 NHCD mills a year. They are performing strongly in a wide range of applications, including:

· Roughing, Intermediate and Pre-finishing mill trains for high-speed wire rod and bar rolling lines

· Whole light and medium bar rolling lines

· Intermediate and Finishing mill trains for special heavy bar rolling lines

· Intermediate and Finishing mill trains for sections rolling lines.

NHCD-dedicated product management teams have been created to assist with the full life-cycle for customers, from marketing and design to quality assurance and control, manufacturing, procurement and ops management.

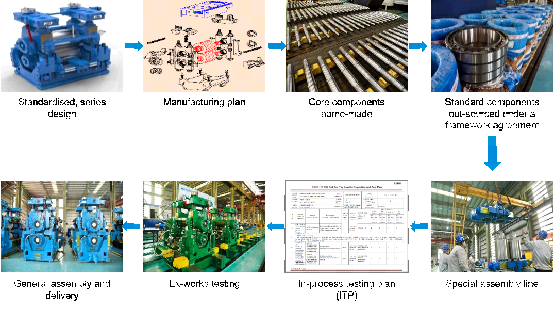

Focussing on standardised, series and refined deliveries, the company has been committed to applying new, flexible manufacturing tech and QC methodology to the product line’s specialist workings and full-process visualised management and control. As a result, the high-quality rolling mill is ensured, from design to manufacture and delivery.

A standard drawing bank has been composed, which is dedicated to the design of a 13 NHCD specification range for the NHCD300-1000 series.

A regulated and highly efficient manufacturing process flow has also been established by employing a welding robot, cluster-based flexible manufacturing, a dedicated assembly zone and integrated mechanical, electric, hydraulic and pneumatic testing.

A highly accurate quality assurance and control system operates for every series of NHCD products and includes:

- detailed quality planning

- strict QC and inspection regulations for raw materials, out-sourced components, procedures and final product for each standard product

- monitoring of all QC via tracking codes for each component or a single unit

- replaceable components and parts

- stable and outstanding delivery quality.

Over 100 rolling lines at plants in China and around the world now feature CISDI’s NHCD, including China’s Baosteel, WISCO, Yongyang Special Steel, Zenith Nantong and YIEH HSING, Thailand’s Qunfeng and Malaysia’s ASSB.

These lines have proven that the NHCD has a critical role in achieving bar dimensional accuracy within a range of 1/3 to 1/4 DIN.

The following chart shows how the outstanding quality of NHCD products are ensured:

The assembled NHCD at CISDI Equipment’s workshop in Chongqing

CISDI-delivered NHCD are rolling at a China’s sections production plant