TC4 titanium alloy plate rolls for the first time at Hanzhong Steel

Date:2024/6/7 Source: CISDI

Intelligent 3,500mm rolling line is CISDI-built

Hanzhong Steel’s intelligent new 3,500mm plate rolling line has produced its first high-grade TC4 titanium alloy plate.

It is the first such line in China’s Shaanxi Province, where the steelworks is based, and it extends Hanzhong Steel’s capabilities to the simultaneous production of steel and Ti alloy plates.

CISDI built the line to an EPC mode and the first steel plate production was recorded in December 2023.

The line’s electric heating furnace reheating and its rolling, heat treatment and straightening procedures are resulting in excellent alloy plate surface quality, thickness accuracy and profile standards.

Ti alloy rolling is a challenging and complicated process. Issues to overcome include a large resistance to deformation, fast temperature drop and a tendency for oxidation to occur in high-temperature and high-pressure conditions.

Titanium is known as an important ‘Metal of the Future’ because of its strength, resilience and lightness. It is as strong as steel but 45 per cent lighter, is twice as strong as aluminium and is highly resistant to corrosion. It also has an extremely high melting point, making it suitable for use in extreme temperature settings.

Ti alloy plate is needed for the aerospace, auto, medical and military sectors.

CISDI took on the line’s technological leadership and was its EPC-based service provider, covering design, supply and construction to technical assistance services.

To ensure the line can produce multiple pieces of Ti alloy plates in a set cycle, CISDI has equipped the line with:

• A smart, mechanised electric heating furnace

• An intensified rolling mill featuring high rigidity and a large torque

• Fully hydraulic straightener with a wide working range

• An advanced water-cooling control system, with flexible functions in opening, closing and switching-over.

To achieve intelligent manufacturing, CISDI and Hanzhong Steel jointly developed the applicative metallurgical regulation and the rolling pass schedule.

Models for hot bar tracking, rolling strategy, load distribution, temperature drop and the processing unit were built to optimise Ti alloy plate production and operation.

The line can automatically learn from its last rolling performance and advise on optimal parameters, automation control and production piece-rate for the next rolling.

Rotation of the hot bar is accurate and automatic, which reduces the need for manual intervention.

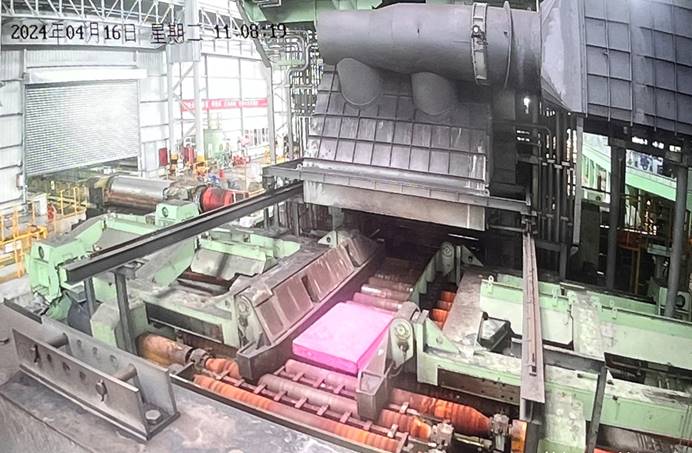

A Ti alloy plate is rolled by the mill at Hanzhong Steel’s 3500mm plate rolling line