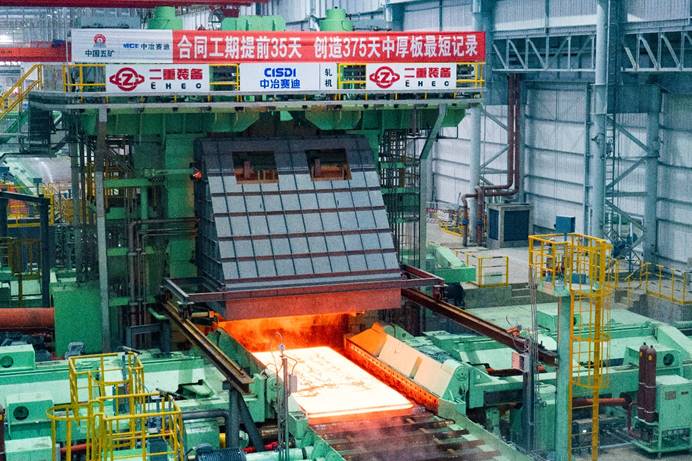

Hanzhong Steel now boasts the first smart heavy plate rolling line in the Shaanxi Province

Date:2024/2/7 Source: CISDI

CISDI worked at record-breaking speed to create the Shaanxi Province’s first smart heavy plate rolling line.

Built to an EPC mode for Hanzhong Steel, which operates under Shaanxi Steel, the line features a single-stand arrangement layout and will hit a yearly million tonne production.

Products will have a maximum dimension of 3,500mm and steel grades will include low-alloy structural, quality carbon structural, welding structural and weather-resisting structural. Boiler and pressure vessel plates will also be produced.

The construction schedule was 375 days, but CISDI managed to process so smoothly, hot commissioning was able to take place 35 days early - a record rate in China.

1) Core equipment applied:

• smart slab reheating furnace

• patent electro-hydraulic direct-drive, high-performance descaling box

• high-rate cooling unit

• composite, heavy-duty stepping-type cooling bed

• roll-cutting crop shear

• roll-cutting double-sided shear

• roll-cutting cut-to-length shear

• scratch-free transfer stand.

2) Automation applied:

• patent full-line automation control software and model

• production control system.

Conventionally, Chinese plants have had to import heavy plate rolling automation software and systems from abroad.

CISDI eradicated that problem for Hanzhong. The line’s first plate was produced using automatic rolling processes, which creates very favourable conditions for ramp-up and future production reaching consistently high standards of efficiency and quality.

3) Digital methods applied:

• three-dimensional designs for the whole line.

The digitally-designed line results in minimal equipment collision or interference and optimal pipeline routes, smoothing constructional quality and ensuring efficiency.

CISDI is now building an integrated melting and rolling smart control centre at Hanzhong. It will be based on the CISDigital® industrial internet platform and will control rolling lines for high-speed wire-rod, combined bar and wire-rod and the production of heavy plate.

Staff who normally work at general scheduling, production and equipment-operating posts across the site will be integrated into one cohesive team at the control centre. This will make the plant a safer place, and will improve operational efficiency.

The centre is soon to implement smart quality, production and equipment operation control and increase visibility of the three-dimensional scenarios.

Tracking of materials will ensure no material sheds onto the land. All data will be thoroughly connected, without dead space. Line quality management will be unified and consistent.

The first heavy plate rolling line in the Shaanxi Province, now operating at Hanzhong Steel

The creation of an integrated melting-rolling smart control centre, featuring CISDI’s patent automation model, software and production control, is now in progress at Hanzhong Steel.