Equipment Manufacturing: CISDI’s CE150 AC-AC frequency control system transforms hot rolling at Gangchen

Date:2023/10/20 Source: CISDI

CISDI’s CE150 AC-AC frequency control system has transformed a hot rolling line at Gangchen Stainless Steel Co in China’s Sichuan Province.

Its application, a first for the Chinese market, has enabled Gangchen’s 1,450mm hot rolling line to upgrade its original main drive system, resolving problems with spare parts and fault rates, which had been caused by its old drive.

The line is now stably producing all required specifications.

Finishing mill stands 5, 6 and 7 were upgraded along with their main drive system, which is now running with three excitation, salient pole synchronous motors. Each features a power rating of 6,000 kilowatts and a maximum rotating speed of 550r/min.

The CE150 control system, one of Beijing-based CISDI Electric Technology Company’s star patent products, has created two significant firsts in other sectors.

2019 saw its first application for double-feeding frequency control governor (speed regulation) of an asynchronous motor. This modified an 80MVA impulse unit’s super-synchronous speed regulation system to digital at the Southwestern Institute of Physics under China’s National Nuclear Corporation.

In 2022 there was another first - it was applied to a heavy bar breakdown mill (spec. 1,350mm) at Tiancheng Aerospace Co in China’s Shaanxi Province. The drive showcased outstanding quality, performance, and reliability and made machine operation easier for workers.

Its launch at the Gangchen hot rolling line means the company is no longer reliant on imports to maintain the exacting performance and reliability requirements of the main drive at its large rolling mill.

This breakthrough was achieved by CISDI Electric’s research and development team, who made continuous advancements in high-performance real-time control platform, motor synchronous vector control, no-circulation commutating logic, and rolling’s main drive control and its intelligent functions.

CE150 AC-AC frequency control system is based on a high-speed real-time Ethernet architecture. It supports a real-time operational system featuring multiple time scales and multiple tasks and communication protocols.

It controls cyclically, to a minimum of 80 microseconds, and provides an innovative, synchronous control method of the variable-cycle regulation system, which centralises three-phase electric currents into one single controller.

CISDI Electric is investing further in its research and development of safer, more efficient and greener energy conversions and applications.

Its power and energy solutions will continue to boost Chinese-made products and benefit the markets.

The Gangchen hot rolling finishing mills with upgraded main drive - CISDI’s CE150

This cabinet houses CISDI Electric’s star product, the CE150 AC-AC frequency control system

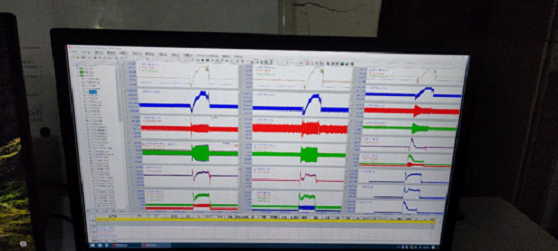

The rolling curve screenshot at Gangchen rolling site, showcasing advanced main drive control results