CISDI-built rotary kiln recovers Zn from dusts at Rizhao Steel’s Yingkou Jinghua

Date:2023/9/19 Source: CISDI

A dust recovery and utilisation project - which features a cluster of CISDI’s state-of-the-art systems - is up and running in China’s Liaoning Province.

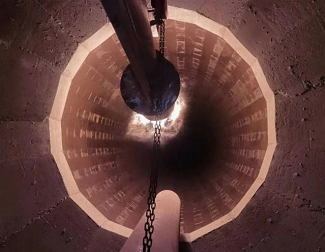

CISDI, the EPC-based service provider for the project at Yingkou Jinghua Steel, which operates under Rizhao Steel, built the project’s innovative, low-carbon rotary kiln, a sintering machine’s feed end water-washing line.

They enable recovery of all zinc-bearing dusts from the plant’s sintering, BOF melting and BF smelting processes.

The kiln has an annual treatment capacity of 200,000 tonnes and the washing line’s annual capability is 30,000 tonnes.

As part of its Solid Waste Treatment Tech cluster, CISDI’s state-of-the-art systems have been applied with outstanding results.

² The coordinated kiln and water washing system removes kalium, sodium, chlorine and other hazardous elements from dusts.

² Feeds are pre-treated for balling, which reduces ringing and stabilises kiln operation.

² An advanced desulphurisation system ensures treatments meet China’s ultra-low emissions standards.

² The rotary kiln-based dust treatment process recovers zinc and ferrous elements from plant-wide dusts, achieving tangible environmental and social benefits and economic savings.

The discharge end of Yingkou Jinghua’s rotary kiln has been ignited for running