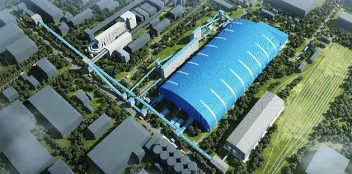

CISDI to build a digital green stockyard for Baotou’s sintering plant in Inner Mongolia

Date:2023/9/19 Source: CISDI

Baotou Steel has called on CISDI’s expertise to create a smart green stockyard for its sintering plant in Inner Mongolia.

The stockyard will provide complete services for the sintering machine, which takes up an area of 265m2.

It will encompass a primary yard, a blending yard, and blending and proportioning, fuel and flux crushing and screening, transporting and utilities systems.

The main yard span is 145m, with a length of 280m.

Multi-layer stacking and reclaiming processes will be enabled by a blending stacker and a bridge scraper blending reclaimer.

Fuel and flux will be crushed and screened by an enclosed loop.

These technologies will ensure stability of the blended ores, as required by sintering production.

A large-power belt conveyor will be driven by a permanent magnetic drum, which will reduce energy consumption and enhance productivity.

To create ultra-low emissions and make Baotou Steel greener and more energy-efficient, multiple clean tech will be built in and monitoring measures will be taken - including mechanical downdraught dust collection, mist-spraying dust suppression and multi-stage cleaning.

CISDI’s expertise in smart production management, information integration and smart control will be applied so the stockyard can carry out automatic proportioning and unmanned stacking.

Artist’s view of the Baotou Steel sintering stockyard, which will be capable of highly-efficient transportation, unmanned operation, digital storage and smart control