Fulfilling contracts: CISDI teams battle against the pandemic on overseas projects

Date:2021/11/16 Source: CISDI

The COVID-19 pandemic has posed severe challenges for the global steel sector. CISDI has gone to great lengths to protect the health of its staff and co-workers when working on projects overseas, while ensuring its contractual responsibilities are met.

The following projects are being achieved successfully:

✧ HPG Hai Duong Steel’s high-temperature, ultra-high-pressure power plant in Vietnam

The Hoa Phat Group placed an order for a 50MW high-temperature, ultra-high-pressure power generator unit with CISDI in October 2019.

The power plant is located at HPG’s Hai Duong Steel and applies the excess heat boiler fuelled by high-parameter steam recovered from the coke oven and by-product gas from the steel production process.

CISDI’s team has been working on-site from June 2020.

The power plant was put on grid for generation in April 2021 and the team is remaining on-site for a further period to ensure it is operating smoothly.

CISDI’s on-site team at HPG’s Hai Duong Steel power generation plant

CISDI engineers are pictured commissioning software for the 50MW power generator at HPG’s Hai Duong Steel

CISDI and the client check the equipment running status

Teams from CISDI and HPG regularly met on-site to discuss the construction schedule

CISDI Vietnam fulfilled its responsibilities to protect the health of all CISDI staff and sub-suppliers onsite

CISDI engineers check construction details onsite

✧ HPG’s Dung Quat Steel reheating furnaces in Vietnam

Last April CISDI won the contract to supply two reheating furnaces for HPG’s Dung Quat Steel plant.

Two furnaces were put into operation in 2021, one for an existing bar rolling line and the other for a new high-speed wire-rod rolling line.

The transporting equipment at each line’s slab warehouse, reheating furnace inlet and outlet and approaching section to the descaler had been also supplied by CISDI.

The operational reheating furnace added to the existing bar rolling line at HPG’s Dung Quat Steel

The CISDI team, pictured at Dung Quat Steel’s reheating furnace site

CISDI engineers are pictured checking the dry-off situation

CISDI engineers are pictured commissioning the furnace software onsite

✧ Empresa Siderúrgica del Mutún Steelworks in Bolivia

CISDI has dispatched a specialist team to the Empresa Siderúrgica del Mutún Steelworks to provide total process consulting services.

The first integrated steelworks in Bolivia, the plant’s projected annual capacity is 194,000 tonnes. Its target market focuses on domestic hot rolled non-flat products.

Construction of the steelworks began in 2019 but was suspended during the pandemic.

The project recommenced in June 2021 and the plant is scheduled to start up in 2023.

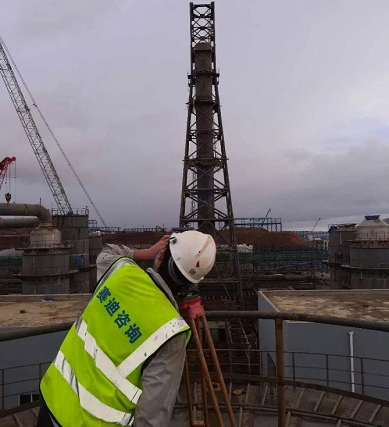

The CISDI team investigates construction progress on-site

CISDI engineers cross-check the alignment between construction and drawings

✧ OBI nickel-cobalt plant in Indonesia

CISDI is providing total process consulting services for a nickel-cobalt production park in Indonesia’s OBI islands, a major project for the country.

Over the past two years, since construction began, a number of CISDI teams have worked on construction management, cost and equipment manufacturing consulting tasks.

Their skill and support will ensure the world’s first nickel-cobalt production process is a success – integrating nickel-bearing laterite mining, concentration, wet and pyrogenic solutions. Production will have a major impact on the world’s new energy and stainless steel sectors.

CISDI’s working group at OBI’s nickel-cobalt production park in Indonesia

A CISDI engineer assists a worker with recording onsite measurements

An engineer from CISDI Engineering Consulting Co. checks the measurement result

CISDI’s OBI team at a meeting to ensure COVID-19 health protection policies are maintained on-site