S&T: Two CISDI inventions win world-class accolade

Date:2020/6/29 Source: CISDI

Two of CISDI inventions have been hailed as world leaders by the Chinese Society for Metals.

Accolades have been given to CISDI’s green, low-consumption and high-speed modular mill and its high-efficiency, high-precision reaction block and shifting unit for hot strip mills.

Modular high-speed mill

It took multiple critical research projects to develop CISDI’s modular high-speed mill - which puts conventional mills in the shade.

It features an inflexible rolling process, a high consumption due to idles and a heavy inventory for roll collars.

CISDI’s modular mill has been applied successfully to bar and wire-rod mills in China and overseas, creating substantial economic and social benefits for Fujian Sanshan Steel, Yasheng Stainless Steel, Xinghua Steel and Liaosheng Steel in China, Sanjia Steel in the Philippines and Qunfeng Steel in Thailand.

The modular mill incorporates the following innovative developments:

● Individual-drive-based flexible rolling for wire-rod structural performance control

● Roll housing assembly coupling rigidity

● Critical component vibration

● Laying tube working curve and mechanical property model

● Rotor kinetics and dynamic speed compensation

A total of 27 patents (including nine invention patents) have been granted. Three patents have been applied for with the Patent Cooperation Treaty and 12 research papers have been published.

Modular mill for a high-speed wire-rod production line in China

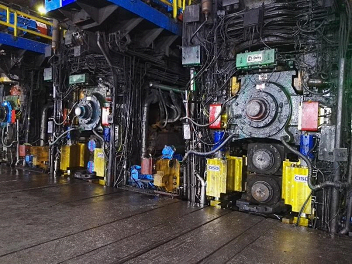

Reaction block and shifting unit for hot strip mills

To solve the high fault rate and unstable operation experienced during the hot strip rolling process, CISDI examined the influence of the reaction block and shifting unit on strip’s profile control, carried out its mechanical-electric-hydraulic coupling simulation and offline simulation loading test and studied the verification method.

A high-precision reaction block and shifting unit has been developed and a verification methodology has been established for the unit’s offline simulation, plus the hydraulic reaction block’s dynamic, static performances and on-load mechanical property.

Offline simulation and verification ensures complete success for the unit’s start-up and reduces the construction cycle by 20-50%, achieving savings of over 20%.

This advanced unit has been granted six patents, including three patents for invention.

Its star application abroad is the 80-inch hot strip mill at TATA Steel’s UK plant. Production data shows a shifting positioning accuracy to within 0.5mm, a 60 per cent reduction in unit fault rate, a 1.4 per cent increase in yield and 35 per cent savings on operation costs.

In China, its latest reference is a package supply to Ganglu Steel’s 1,450mm hot strip mill.

The CISDI-supplied reaction blocks supplied to TATA Steel UK