S&T: Initial use of CISDI’s stationary work roll bend-shift expertise

Date:2019/6/18 Source: CISDI

Initial use of CISDI’s stationary work roll

bend-shift expertise

─── Changing

movable work-roll bending and shifting mechanism to a stationary one trending

toward hot mill upgrades

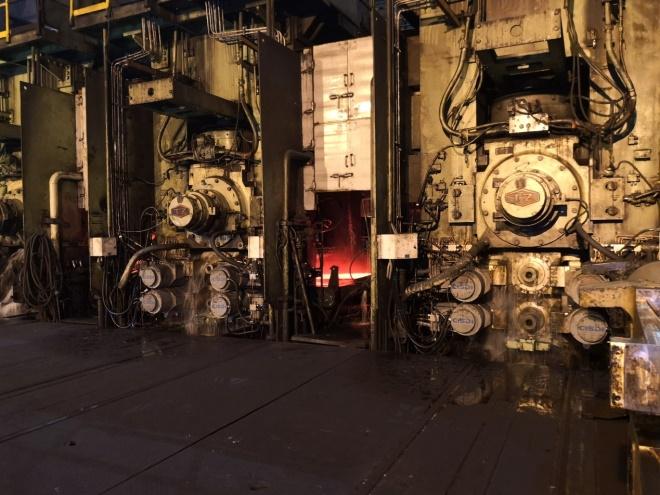

Tangshan Steel’s Ganglu finishing mill has started up its work roll bending and shifting mechanism.

Built by CISDI to an EPC mode, the mill has been switched from a movable bend-shift mechanism to a stationary by integrating mechanical, hydraulic, electric and automation control systems.

The bend-shift

mechanism is critical to good rolling stability and product quality at a hot

rolling finishing mill, but Ganglu’s moveable mechanism was causing operational

problems.

The first

application at Ganglu has been on schedule and product quality standards have

been achieved. This lays a solid foundation for CISDI to commercialise the

expertise it has developed.

Ganglu’s finishing

mill features CISDI’s stationary work roll bend-shift mechanism